The ESTM Heavy Duty Series hydraulic rock breakers are developed for demanding demolition and rock excavation projects where reliability and consistent impact power are essential. Every excavator rock breaker in our range is engineered to perform under extreme working conditions while maintaining mechanical simplicity and long service life.

Our philosophy is simple: deliver maximum breaking force with minimal downtime.

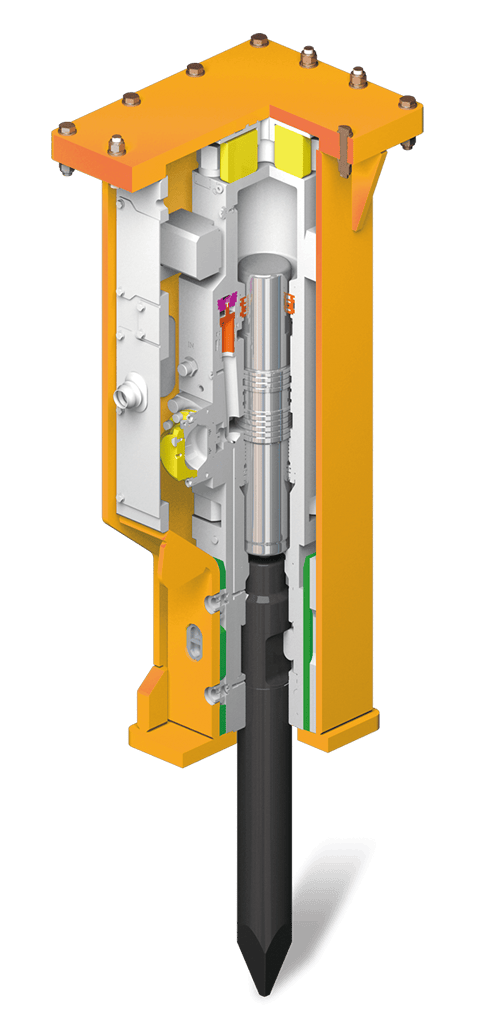

One of the key strengths of the ESTM excavator rock breaker is its simplified internal design. With only three primary moving parts: the piston, control valve and pilot valve. The internal valve system is fully housed within the breaker body, protecting it from dust, debris and impact damage. This compact and protected design improves long-term reliability and reduces the risk of unexpected breakdowns.

Mechanical simplicity is one of the main reasons ESTM hydraulic rock breakers achieve long service intervals and predictable operating costs.

At the heart of every ESTM hydraulic rock breaker is a high-efficiency impact system designed to transfer maximum energy from the excavator to the material.

The integrated nitrogen gas accumulator absorbs piston recoil and recycles that energy into the next blow. This increases impact force, improves energy efficiency and reduces stress on the carrier. Combined with the dual speed control system, operators can adjust impact frequency depending on material hardness, ensuring optimal performance in both concrete demolition and hard rock applications.

The result is stable, powerful and consistent breaking performance throughout long working hours.

At the heart of every ESTM hydraulic rock breaker is a high-efficiency impact system designed to transfer maximum energy from the excavator to the material.

HARDOX® steel wear plates are integrated into exposed areas to reduce structural wear and extend service life. Oversized tool retaining pins further enhance durability while simplifying replacement procedures.

To protect internal components, ESTM rock breakers feature an anti-blank firing system that prevents dry firing damage. This significantly increases piston and bushing lifespan while also protecting the excavator’s hydraulic system.

Together, these features make ESTM hydraulic rock breakers ideal for quarry, mining and heavy demolition work.